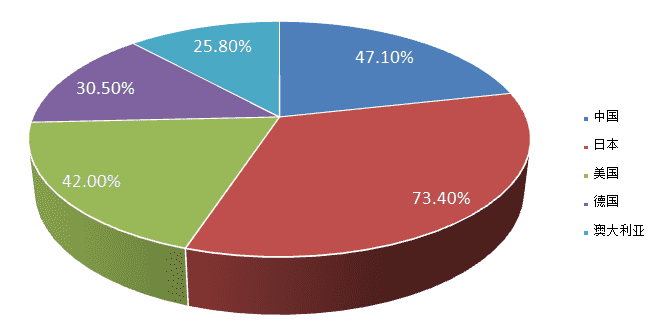

According to the estimates of the World Health Organization (WHO), the number of people suffering from myopia is the biggest among the people with sub-health eyes, and it has reached 2.6 billion in 2020. Myopia has become a major global problem, particularly serious in Asia. The myopia rate in China is 47.1%, nearly half of the total population. It means one out of every two people is nearsighted.

Myopia Rate in Different Countries

Nowadays, with the significant increase in myopia rate, the rate of wearing glasses is also increasing year by year. As one of the myopic patients, have you paid attention to the factors that determine the lens quality when considering eyewear design and lens function?

Let's learn something important about the lens material and refractive index.

A good lens requires uniformity, transmittance and clarity. The most common lens today is the result of years of exploration.

| The development of lens materials

Most of the earliest lenses were made by hand with natural materials such as quartz and crystal. With the development of glass production and industrial technology, natural materials were quickly replaced by optical glass which began to provide more functions. From the 1960s to the 1980s, resin materials, made from petroleum, have replaced glass for its better optical properties, safe processing and thin physical properties, and become the main material of eyeglass lenses until now. |

As the most popular lens material in the market, resin materials are mainly represented by CR-39 resin developed by PPG, MR resin developed by Mitsui, and KR resin developed by KOC, Korea, etc.

The lens material determines the refractive index of the lens. Lens refractive index is the ratio of light propagation speed in vacuum to light propagation speed in lens material, reflecting the refraction ability of lens to light. Generally speaking, the higher the refractive index of the lens, the thinner the lens.

At present, Universe Optical has refractive index of 1.50, 1.53, 1.56, 1.60, 1.67, 1.74 and other indexes of lenses. In terms of materials, we have maintained close strategic cooperation with PPG of the United States and Mitsui Chemical of Japan as well as other raw materials companies with outstanding achievements.

CR-39 raw material purchased from PPG, USA, is used to make refractive index 1.50 lens. It is more favored in the market because of its high Abbe coefficient, excellent optical performance, safety performance and more cost-effective.

The 1.53 refractive index lens is derived from a special material, Trivex, also from PPG in the US. Trivex lens material is extremely impact-resistant. Because they are lighter than standard lenses, Trivex lenses are very good choice for children's eyewear, rimless eyewear, sports goggles, safety eyewear, and athletic eyewear.

With the development of glasses, the "lens", as the main accessory of glasses, is constantly innovating and upgrading with the change of times. Universe Optical 1.60, 1.67, 1.74 high index lens raw materials are made of MR series of Mitsui Chemical. MR series are high quality and advanced materials, with high refractive index, high Abbe number, low specific gravity, high impact resistance and other advantages.

The continuous improvement of lens material R&D and technology boost the lens products innovation. The lens raw materials determine the stability of quality, transmittance, clarity and visual effect.

Universe optical has been adhering to the policy of win-win cooperation and mutual achievement. We listen to the voice of customers, get to know customers' needs, pay attention to the market tendency, so as to create a clearer vision.